Home » 3D technology supports Hanford design work

3D technology supports Hanford design work

August 15, 2019

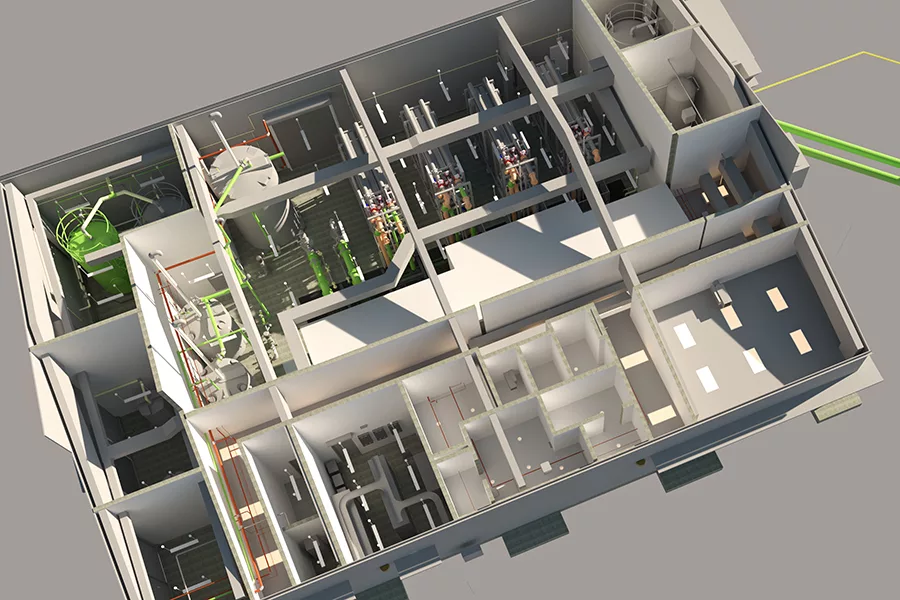

Mission Support Alliance is using industry best

practices and 3D modeling software to help design a new water treatment

facility on the Hanford site.

The Hanford contractor’s 3D modeling is a vital design

tool, enabling timely completion of complex projects. In this approach, also

known as building information modeling, or BIM, the designers “build” the

structure and process elements in a three-dimensional space, allowing personnel

from various disciplines to “see” the potential facility and identify potential

issues early in the design process, before any physical walls or components are

put into place.

“This use of 3D software has allowed us to achieve

improved design and cost savings,” said Sharee Dickinson, director of

infrastructure and services with the U.S. Department of Energy Richland

Operations Office, in a media release.

One example of cost savings resulting from this process

was the removal of an auxiliary building. Initially, plans included a second

building—about 1,500 square feet—to house backflow preventers and isolation

valves for the water treatment plant. To provide adequate freeze protection,

this second building would have had to be heated as well, resulting in

additional capital costs and ongoing operational costs.

Using the 3D software, MSA crews were able to make some

adjustments in the plans for the process room floor and with only a small

expansion of the main building blueprint, bring those components inside the

main building, eliminating the need for the second building.

The use of 3D visualization also enables detailed and

highly interactive design reviews with the MSA water and sewer utility

operators, who will be the end-users. Operators can conduct virtual tours of the

designed facility, allowing timely and efficient changes. The model also

accommodates traditional drawing formats and “flat” construction drawing

production by cutting virtual lines and projecting a traditional

two-dimensional image.

Dan Parr, who works with MSA’s reliability projects

group, is the project manager for the water treatment facility. “With the

ability to ‘remove’ the roof and look inside the facility during the design

process, we’ve been able to evaluate how the operators will function in the new

building, and make adjustments long before construction begins. This will

reduce the number of costly last-minute changes during the construction

process, and ensure a better functioning facility at the end of the project,”

he said in a release.

During one model review meeting, the future operations

team wanted to look inside the pipe gallery area. One planner noted that while

it was the appropriate design for construction, it might hinder maintenance

operations in the future. Operators were worried that if piping or pump

components needed to be repaired or replaced, there would not be enough space

for workers to do so. Working with the designers and engineers, they were able

to adjust the spacing of the pipes, and placement of the light fixtures and the

deck grating to provide adequate space for future maintenance needs.

The software being used, a combination of both Autodesk

Revit and Navisworks 3D, is used by municipalities and engineering firms

worldwide.

MSA contracted with HDR in Pasco to develop the facility

design using this software.

Design of the water treatment facility is now 90 percent

completed and construction is expected to begin in early 2020, with the

facility targeted to be in service in 2021.

The $13.9 million project will provide reliable

water to users in the center of the Hanford site.

Local News Science & Technology

KEYWORDS august 2019