Home » Robotic arm gives Washington apples a helping hand

Robotic arm gives Washington apples a helping hand

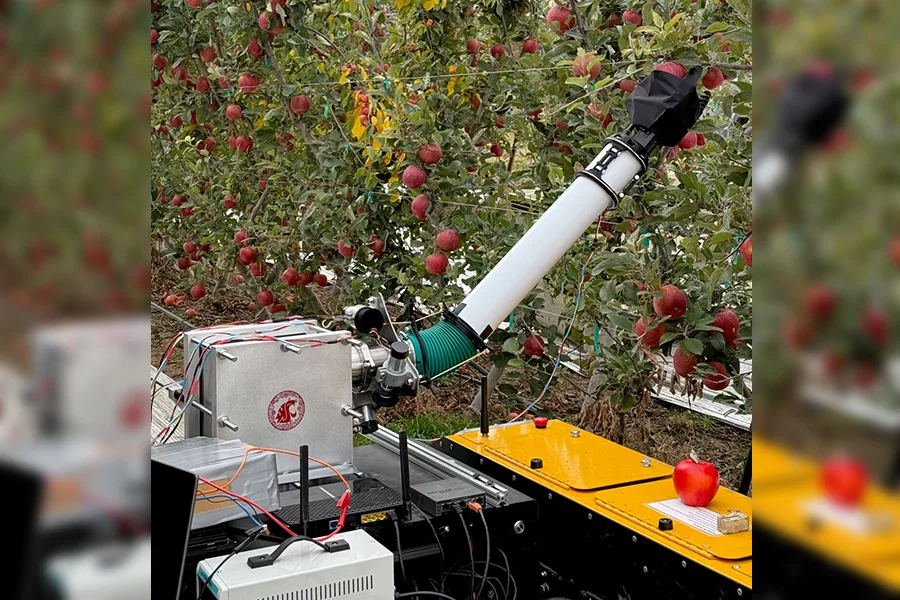

Tree fruit growers worldwide are facing labor shortages for critical operations like harvesting and pruning. WSU researchers are developing low-cost robotic solutions to aid the industry.

Courtesy of Ryan Dorosh/WSUJanuary 19, 2026

Researchers at Washington State University, along with those at the Prosser Research Extension Center, have developed a low-cost robotic arm that can pick apples, potentially lending a mechanical hand to orchard workers and easing the crunch of seasonal labor shortages.

Made with a 2-foot-long inflatable fabric arm, the robot weighs less than 50 pounds and can detect apples, then extend and retract to pick a piece of fruit. Because of its lightweight and soft nature, it’s safe to use with people nearby and won’t harm delicate branches or apples. The materials to make the arm cost about $5,500.

The robotic process takes about 25 seconds, still far slower than human pickers, who can pick an apple every 3 seconds. Researchers are working to refine some of the mechanical components as well as the detection system, which hinders the robot’s picking more than the actual movement.

Researchers also plan to develop the arm’s ability to do other orchard tasks, like pruning, flower thinning and spraying, in hopes that farmers will eventually be able to buy inexpensive robots which can perform several tasks.

Tree fruit growers throughout the world face labor shortages for harvesting, pruning and other critical operations. Washington leads apple and sweet cherry production in the U.S. and farms employ hundreds of workers each year for orchard operations.

Farmers struggle to meet their needs for workers during harvest season due to an aging population and decrease in migrant farmworkers.

Latest News Local News Agriculture Science & Technology

KEYWORDS January 2026

Related Articles

Related Products