Home » Bechtel’s vitrification plant heating up in 2021

Bechtel’s vitrification plant heating up in 2021

April 16, 2021

Progress is heating up at Hanford’s Waste Treatment and Immobilization Plant.

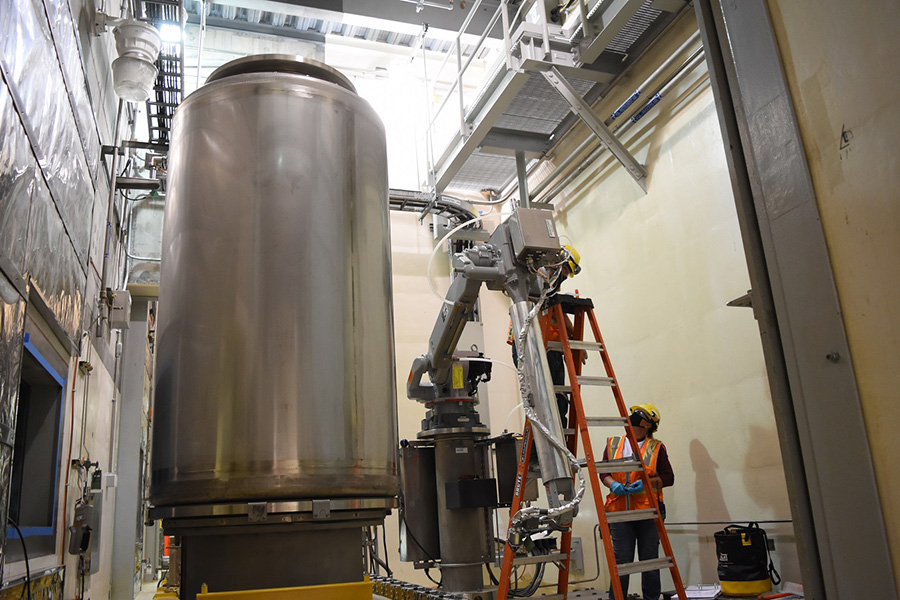

Also known as the vit plant, the project is taking a permanent step forward at the end of this year – heating up our first 300-ton low-activity waste melter.

The melters are the heart of the vitrification process, which will turn Hanford’s waste into a solid glass form for safe storage.

When operational, the melters will be used to combine low-activity waste and glass-forming chemicals at 2,100 degrees Fahrenheit before the mixture is poured into stainless steel containers to cool and solidify. The melters will remain at operating temperature through hot commissioning in 2023 and into long-term operations.

Our progress toward melter heatup and preparing to treat tank waste using the Direct-Feed Low-Activity Waste (DFLAW) approach is possible thanks to the resilience, hard work and dedication of our team. Despite the unprecedented challenges of 2020, we continued to move the project forward.

Just a few of the accomplishments from last year include:

- Completed Low-Activity Waste (DFLAW) facility construction

- Completed Effluent Management Facility (EMF) construction

- Completed Analytical Laboratory (Lab) startup testing

- Completed handing over of all 14 utilities and support facilities (balance of facilities) to plant management.

Our team members have adapted and stepped up, never wavering on their commitment to safety and quality. Led by Bechtel National Inc., our team includes Amentum, the Waste Treatment Completion Company and members of the Central Washington Building Trades.

Processing tank waste is just around the corner.

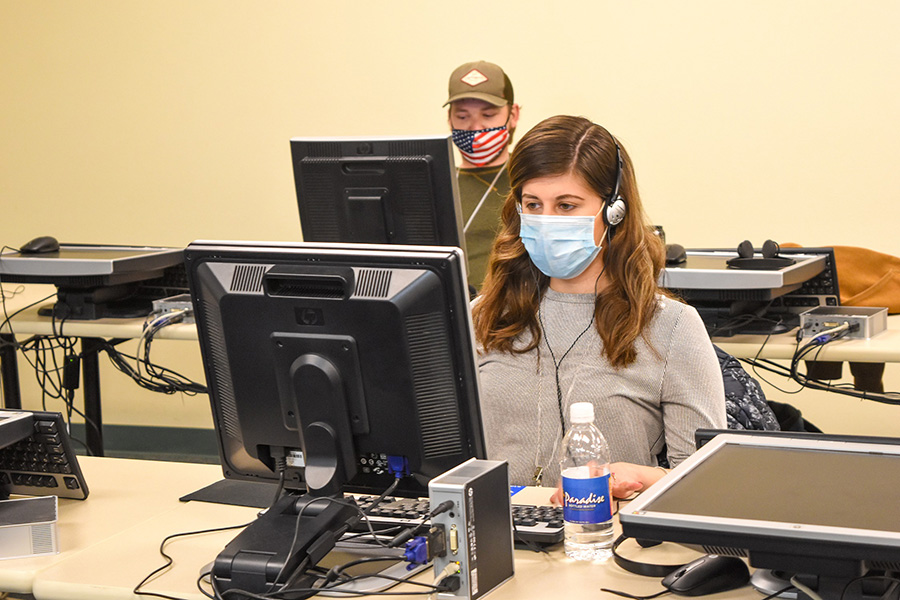

Vit plant facilities and systems continue to be handed over regularly, and our plant operators are in their second year of working 24/7 shifts.

Our final group of commissioning technicians completed their five-month intensive training program in November. They became part of the approximately 140-person commissioning technician team that will operate the vit plant.

Our job site continues to look more like an operating facility, with temporary structures coming down and paved roads going in.

We kicked off 2021 by celebrating the completion of DFLAW facility construction, meaning construction is done on the vit plant facilities needed to start treating tank waste.

Soon after, we announced the Lab was deemed “ready to operate.” This means the facility and its team are prepared to support cold commissioning, when simulated waste is run through the plant to ensure systems are working properly under operating conditions.

We will continue to build momentum this year by demonstrating backup systems will temporarily power the melters in case there is an electricity outage. This is important because once started, the melters need to stay hot until they are replaced at the end of their service life.

After that demonstration, we’ll proceed with heating up the first melter by the end of the year. Other 2021 goals include:

- Completing all procedures required for operations, which we achieved in March.

- Completing testing of all the components and systems in the Effluent Management Facility, which treats secondary waste from the DFLAW facility.

- Completing testing of all the components and systems in the DFLAW facility.

- Completing testing of HEPA filters in the Analytical Laboratory.

The vit plant team works closely with our U.S. Department of Energy customer and other Hanford contractors as One Hanford. We collaborate with the Washington State Department of Ecology and regulators to achieve our mission, and we continue to support small businesses in the region, state and the Tri-Cities itself.

Community is more important than ever right now.

Our team continued to step up last year, donating more than $275,000 to local charitable organizations, such as United Way, Junior Achievement and Toys for Tots.

The vit plant was the top local fundraising team for Polar Plunge and Special Olympics last year. This year, they built on that success to become the top fundraising team in the state, raising more than $25,000, making them the top fundraising team in the state.

In addition, prime contractor Bechtel National Inc. made corporate donations, including $100,000 to the United Way Covid-19 Response Fund.

As the vit plant continues to drive toward completion, we want to thank the thousands of skilled craft and professionals – current and past – who have worked on achieving this piece of history. We also thank the Central Washington Building Trades and their leadership for being incredible partners over the years.

Each of our team members has brought expertise and helped make this plant a modern marvel that will achieve its mission – cleaning up Hanford’s legacy waste. They have truly been part of One Team and One Hanford and contributed to the achievement of the future milestones we can’t wait to celebrate this year.

Valerie McCain is senior vice president and project director at Bechtel National Inc.’s Waste Treatment and Immobilization Plant.

Hanford

KEYWORDS april 2021