Home » Vit plant readies to heat up world’s largest melter

Vit plant readies to heat up world’s largest melter

April 13, 2022

In 2022, the Hanford Vit Plant team will tackle some of the most complex and challenging milestones on our journey to transform low-activity radiological and chemical tank waste into a glass form safe for long-term disposal. This process, called vitrification, will allow us to protect the Columbia River and its rivershore communities.

It’s an exciting time to be part of the project, also known as the Waste Treatment and Immobilization Plant project. The efforts of thousands of people – our team, customers, suppliers, stakeholders and alumni – will culminate more than two decades with three historic steps:

- Heating up the first melter. The melters are housed inside the Low-Activity Waste Facility and are the heart of the vitrification process, which will turn Hanford’s waste into a glass form for safe disposal. When operational, the melters will mix low-activity waste with glass-forming chemicals at 2,100 degrees Fahrenheit. The mixture is poured into stainless steel containers to cool and solidify before being disposed at the Hanford Integrated Disposal Facility.

- Conducting cold commissioning. In this step, our team will run chemical simulants through the plant to demonstrate the operation of the vitrification process before tank waste is introduced into the plant in 2023.

- Heating up the second melter. We will apply lessons learned from the first melter heatup to bring the second one up to temperature after cold commissioning is complete. Both melters will remain at operating temperature into long-term operations.

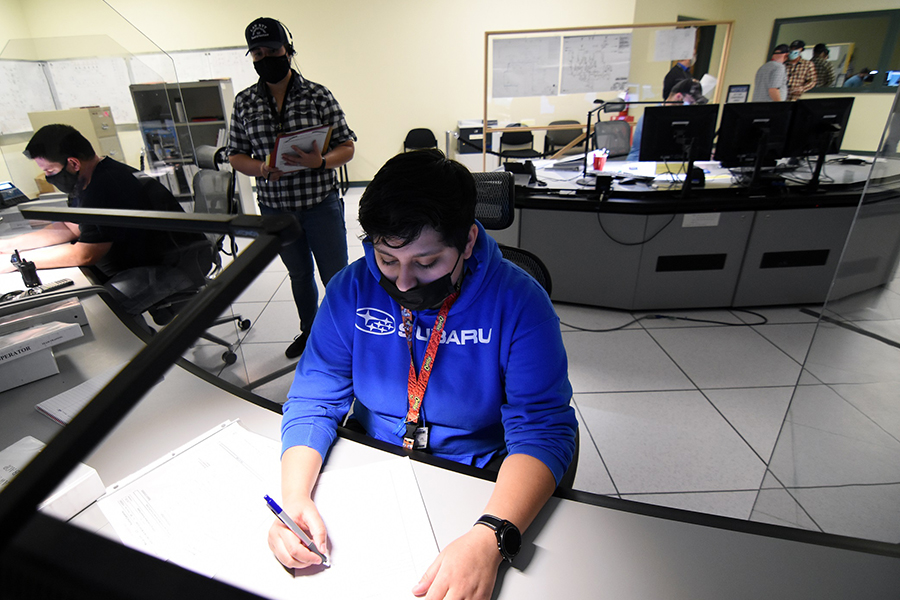

Our team has worked diligently on 24/7 shifts to ensure we have the people, plant and paper/processes ready to move forward in bringing the largest melters in the world into operation. We started 2021 by marking all construction complete, a hallmark moment for this project. Throughout the year, we celebrated several significant achievements in all three of these areas.

Workforce

By collaborating with the Central Washington Building Trades, we have hired many of the teammates needed into permanent positions, from laboratory technicians to radiological control technicians, and qualified key people for running the facility. Additional team members will be added this year to complete the hiring needed to fill the full team. Our team has grown and changed as we finished construction and shifted fully into commissioning.

Plant testing

We completed startup testing of all equipment, systems and facilities.

We successfully conducted a test to demonstrate that the plant could be brought back online safely if it experienced a loss of off-site power.

We began testing the movement of stainless-steel containers that will carry vitrified waste in the plant by moving them through the process using remotely operated crane systems.

Procedures and permits

Our team created almost 5,500 step-by-step procedures required for operation of the systems and facilities.

The Washington Department of Ecology approved multiple permits necessary for both the Low-Activity Waste and Effluent Management Facilities.

These are just a handful of the accomplishments from 2021 that were made possible because of our team, our U.S. Department of Energy customer, regulators and many businesses in the Tri-Cities and across the country.

We safely advanced the project across all fronts thanks to our team’s focus on the right behaviors, teamwork, commitment and overall resiliency.

Our team is also incredibly generous, donating more than $340,000 to the Tri-Cities community in 2021. Those donations cross the spectrum of need in the community, such as the Children’s Reading Foundation, Toys for Tots, Bikes for Tikes, Special Olympics, United Way, STEM Foundation and Boys & Girls Clubs.

I’m so proud of the team and look forward to building upon our successes in 2022. I can’t think of a more exciting time to have the privilege of being a part of the vit plant team and advance our important national mission.

Valerie McCain is senior vice president for Bechtel National and project director at the U.S. Department of Energy’s Waste Treatment and Immobilization Plant.

Hanford

KEYWORDS april 2022