Home » Modern technology offers new look inside Hanford’s sealed nuclear reactors

Modern technology offers new look inside Hanford’s sealed nuclear reactors

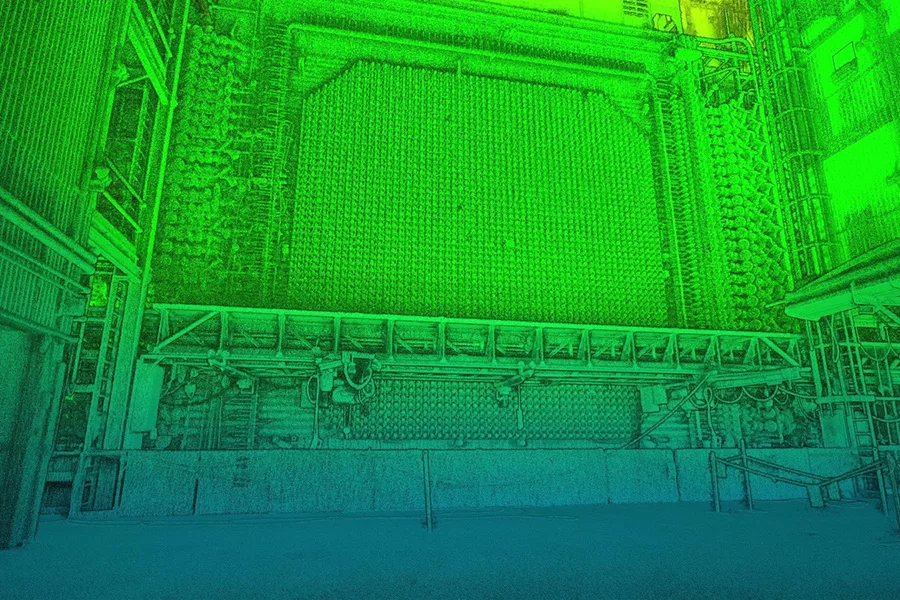

An image of the interior of the safety enclosure of F Reactor created using lidar technology. Such imaging will assist Hanford site workers to better monitor the interior structure of cocooned reactors.

Courtesy DOEAugust 22, 2025

Workers at the Hanford site used new imaging technology to inspect the Hanford Site’s decommissioned nuclear reactors, revealing a detailed look inside the sealed enclosures that will help monitor them more safely and affordably.

Crews with Hanford Mission Integration Solutions (HMIS) recently conducted routine 10-year inspections of the safe storage enclosures for six of the Hanford site’s seven cocooned reactors, according to a release.

Members of the Engineering and Long-Term Stewardship teams at Hanford Mission Integration Solutions inspect the interior of the F Reactor enclosure for structural changes since the last inspection 10 years prior.

| Courtesy DOEThe inspections are part of the Long-Term Stewardship Program, which handles tasks from surveillance and maintenance after areas are cleaned up to natural and cultural resource management as required by federal law and treaties with tribal nations.

“These inspections are critical to ensuring the cocooned reactors continue to function as designed,” said Tashina Jasso, acting director with the HFO’s Site Stewardship Division, in a statement. “The inspections are part of our commitment to reducing risk and preserving infrastructure for long term management and safe disposal.”

While the reactors are all inspected visually by drone every year, internal checks require more planning and safety consideration. That led to the decision to bring lidar technology into the enclosures to image the insides of the safety enclosures.

Long-Term Stewardship Project Manager Deanna Breckon uses a lidar backpack to map the interior of the F Reactor enclosure. Lidar, which stands for light detection and ranging, measures the time for lasers to be reflected back off a surface.

| Courtesy DOELidar, which stands for light detection and ranging, measures the time for lasers to be reflected back off a surface. Heavily used in mapping applications, it can also create 3D representations.

For HMIS workers, the technology provided a way to capture a detailed picture of conditions and identify potential issues.

“Lidar technology has been a game-changer in how we assess these structures,” said Deanna Breckon, project manager with HMIS Long-Term Stewardship. “It allows us to see things we couldn’t before and ensures we are taking the right steps to maintain safety.”

Latest News Local News Hanford Science & Technology

KEYWORDS August 2025

Related Articles

Related Products